What Is Aluminum Powder Used For

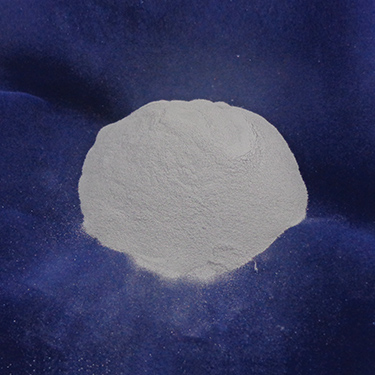

99% Aluminum Pulverisation

- Overview

- Nominal Composition

| Aluminum Pulverization is used in the production of many types of explosives and fire works. Information technology is as well employed in the manufacturing of certain types of electronics. Powdered aluminum is included in many paints and sealants. Sure products pattern to carry electrical electric current, such as solar cells are often fabricated using aluminum powder. Rocket Fuel is often made with aluminum and many solid rocket fuels are based on chemical reactions involving this metal. | |

| Forms: |

|

|---|---|

| Belmont Product Code | 1300 |

| Nominal Limerick: |

|

|---|

- Datasheet

- SDS

Related products

RELATED POSTS

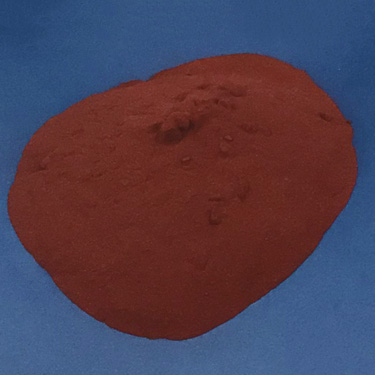

The Applications for Iron Pulverisation

Many metals are used in their pure powder form in the manufacturing of various products. At that place are many grades of iron powder, equally they are categorized based on their purity, grain size, density, and the manufacturing method. So the iron pulverisation will be modified to fit into the application. Iron Powder Backdrop Fe pulverisation is…

Silicon Pulverisation Applications and Uses

Many manufacturers require pure metals in a range of different shapes to add every bit additives when making products. These metals provide unlike properties to the products, such as hardening metals, providing corrosion resistance, or reduces oxidation. Silicon is ane metal found in a wide range of industries due to its versatility and toll-effectiveness. Pure silicon…

Powdered Metals Providing Versatile Appearance in Painting Applications

During the concluding stage of the manufacturing process, many products and components are coated with a paint to create a more aesthetically-pleasing appearance likewise as to seal over the material to amend corrosion and stain resistance. When talking about most painting applications, people are aware of both oil-based and water-based paints. Nevertheless metallic paints…

Discussion and Current Applications for 3d Metallic Printing

Are you experimenting with 3D metal printing? Current manufacture trends say that 3D metal printing will overtake casting by 2020, according to Spotlight Metal, and it's already being used for small-scale batches of products and parts. If you're on the forefront of this new manufacturing process or thinking about information technology, you're probably interested in the…

3D Metallic Printing: Alloys and Powder Types and Specs

Whether creating prototypes for application components, precision gears, or jewelry, more manufacturers are turning to the capabilities provided by 3D metal printing. Besides called additive manufacturing, this process relies on technology that uses a metal powder in a layering process to produce the three-dimensional part. There are several methods used in the 3-D metal printing…

Common Uses for Powdered Metals

If y'all are debating the best grade or metal to use for your manufacturing business, you may exist surprised to learn that powdered metals have just as many uses every bit their metal alloy counterparts. In fact, adding a powdered metal to your master alloy can increment certain desirable properties and decrease certain undesirable properties. Our…

Cold Working Aluminum Alloys

When considering working and manufacturing with metals, particularly with aluminum, the commencement thoughts are centered on the heating process with hot furnaces where the metal is heated to extremely loftier temperatures and so wrought or bandage into grade. Nevertheless, there is another blazon of procedure to strengthen the metallic that involves calculation other alloys to…

Custom creations

Aluminum master alloys help metallurgists fine-tune alloys to create materials that are stronger, lighter, and more easily candy Aluminum is the most abundant metallic element in the Earth's chaff—it's even more than common than Iron. In its pure form, though, it's soft and malleable. It needs to exist alloyed with other elements, including Fe, Zinc, Silicon,…

Creating complex shapes

Powdered metals help engineers produce parts price-finer What is the best style to make a 3-D part out of metal? It depends. There are a number of considerations involved, including time and coin. To create parts, manufacturers tin choose either a subtractive or an additive manufacturing process. Subtractive manufacturing involves taking a block of material…

What Is Aluminum Powder Used For,

Source: https://www.belmontmetals.com/product/99-aluminum-powder/#:~:text=Aluminum%20Powder%20is%20used%20in,in%20many%20paints%20and%20sealants.

Posted by: coxource1977.blogspot.com

0 Response to "What Is Aluminum Powder Used For"

Post a Comment